SAFETY AND TACTICAL MARKINGS

SAFETY

Products tested and certified

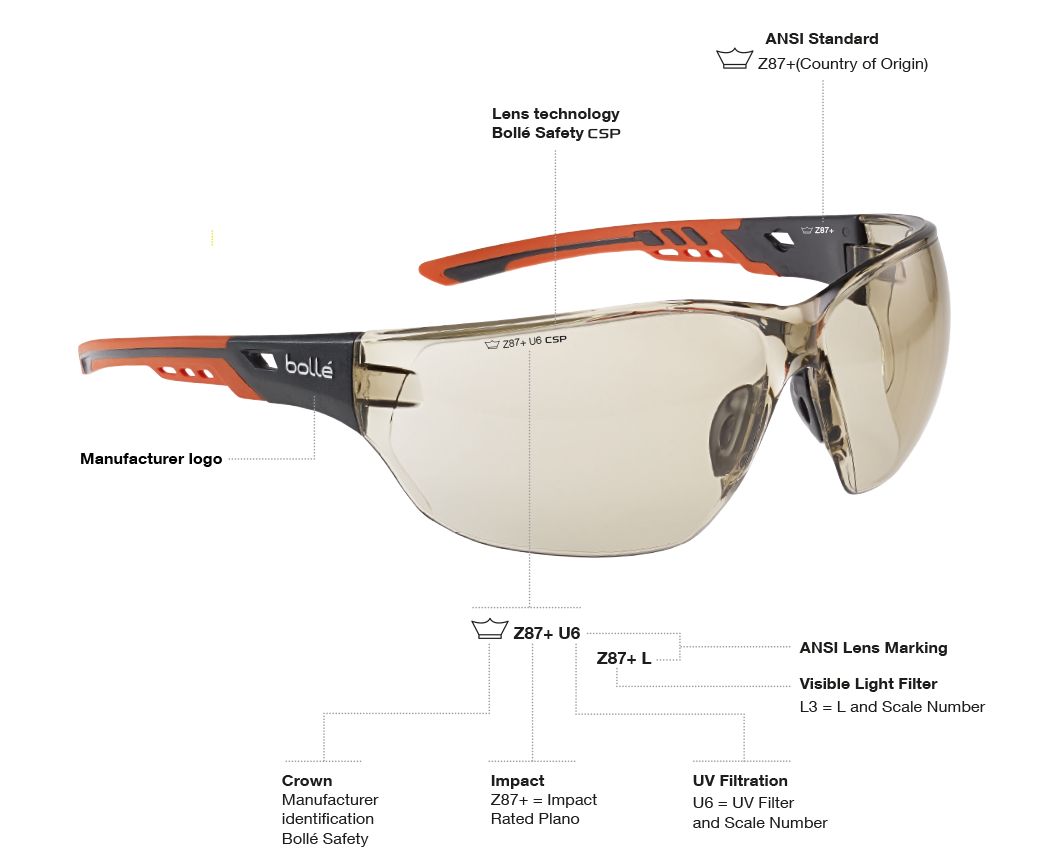

Bollé Safety lens and frame markings are specific to each product. Each marking corresponds to a very specific use. Certified by independent laboratories this information guarantees protective eyewear quality and resistance.

IMPACT

The Z87.1 2003 standard previously classified personal protectors as “basic or high impact” devices. In the ANSI Z87.1-2010 standard, personal protectors are rated as either “impact” or “non-impact” protectors.

To be considered an impact protector, the device must meet the high velocity and high mass tests. Once these devices have passed the test, they will carry the Z87+ stamp on both the frame or lens housing and lens.

Additionally, prescription products meeting this requirement will carry the marking Z87-2+. Non-impact protectors (those that do not pass all high-impact testing) will be designated only as Z87 (not to include the + sign).

OPTICAL RADIATION

Spectral transmittance categories have been expanded to allow matching and selection of filters for radiation hazards in greater specificity than the previous standard.

DROPLET, SPLASH

Dust-The new standard has expanded to assist users in identifying specific protectors that may be appropriate for the hazard.

The following markings indicate the hazard: D3-Liquid Splash, D4-dust, D5-fine dust. This rating will be marked on the lens and the frame of the approved device.

Bollé Safety offers a wide range of safety eyewear with optical markings specific to each risk and type of activity.

What is the assessment of occupational hazards?

Assessment of occupational hazards involves identifying and ranking hazards in the workplace to implement relevant protective measures. It is the initial step in occupational health and safety. It is essential to check adequacy between product markings and standards markings.

Brief Overview of the ANSI Z87.1-2010 Standard

On April 13, 2010 the American National Standards Institute (ANSI) announced a new edition of the ANSI/ISEA Z87.1 standard. The new edition titled, “American National Standards Institute for Occupational and Educational Personal Eye and Face Protective Devices” updates the previous version, Z87.1-2003.

Significant Changes to the Standard

The new standard is hazard based requiring employers to select protective devices based upon the workplace. This is a change compared to the 2003 standard, which focused on the protector type. Specific evaluation is now required for workplace hazards such as impact, optical radiation, droplet and splash, dust and fine dust particles. As the 2010 standard is radically different, the product markings have changed. Users will need education on matching the hazard that they need protection from with the marking on the product.

UKCA

The UKCA (UK Conformity Assessed) marking is a new marking used for goods sold on the market in Great Britain (England, Wales and Scotland). It covers most goods which previously required the CE marking.

| TYPE OF MARK | DESCRIPTION | MARKING |

|---|---|---|

| Impact | Impact Rated Plano Impact Rated Prescription |

Z87+ Z87-2+ |

| Non-impact | Plano Prescription |

Z87 Z87-2 |

| Lens type | Clear Welding UV filter Visible Light Filter IR Filter Variable Tint Special Purpose |

None W and Shade Number (Shades range from 1.3 to 14 - the higher the number the darker the lens) U and Scale Number (Scale ranges from 2 to 6 - the higher the number the highest protection from far and near UV) L and Scale Number (Scale ranges from 1.3 to 10 - lower numbers providing greater light transmittance) R and Scale Number (Scale ranges from 1.3 to 10) V S |

| Use | Splash / Droplet Dust Fine Dust |

D3 D4 D5 |

Bollé Safety’s environmental commitment:

Bollé Safety is committed to offering an alternative "environmentally responsible" option that is in tune with the needs of its customers.

In recent years, Bollé Safety now distributes its products in individual recyclable bags.

From manufacturing to logistics

All Bollé Safety products are subject to regulation REACH (Registration, Evaluation and Authorization of Chemicals), which ensures that all substances used on Bollé Safety products do not harm health or the environment.

TACTICAL

Products tested and certified

The Bollé Safety Standard Issue range has been designed, tested and certified to be fully compliant with American standard ANSI* Z87.1-2010 (high resistance to the most extreme impacts). It also meets ballistics standards GL-PD 10-12, MIL-PRF-31013, MIL-DTL-43511D and MIL-PRF-32432 defined by the United States Department of Defense.

* American National Standards Institute

STANAG 2920 & 4296

STANAG 2920

This standard concerns bulletproof materials and combat clothing. In the case of Bollé Safety Standard Issue, goggles and glasses are subjected to impact tests using projectiles simulating ballistic fragments.

All the tests allow to calculate a V50 corresponding to the speed at which the projectile has a 50% chance to perforate the material. The value of the V50 varies according to the nature of the materials and therefore the colour of the lenses.

STANAG 4296

The STANAG 4296 marking guarantees the ballistic resistance defined by STANAG 2920 but also incorporates certain use criteria (comfort, fog reduction, scratch resistance, etc.) and criteria relating to the general appearance (brightness, compatibility with other equipment, etc.).

MIL-PRF

MIL is an evolving American military standard: Mil - PRF - 31013 (1996) and Mil 43511D (2006) were replaced by GL-PD-10-12 (2010), which will then be revised and transformed into MIL-PRF-32432 in 2013.

These military standards specify criteria with which products must comply in terms of eye protection. These criteria concern in particular ballistic protection, optical qualities, product durability, etc.

The MIL standard which is used as a reference standard by many countries.