Occupational risks:

Assess them properly to select the right protection

Assessing occupational risks is the first step in drawing up company health and safety policy.

The selection of eye protection is part of your duty as an employer. It is important to clearly identify the types of risks present in order to provide each employee the suitable equipment and to check that the risks, directives, standards and markings on the protection are all in line with each other.

To help you with this task, our optics department has selected the best technology and included it in our EXCELLENCE offer: lens materials, design quality, coatings and tints to protect and optimise your employees’ eyesight.

LENS MATERIAL

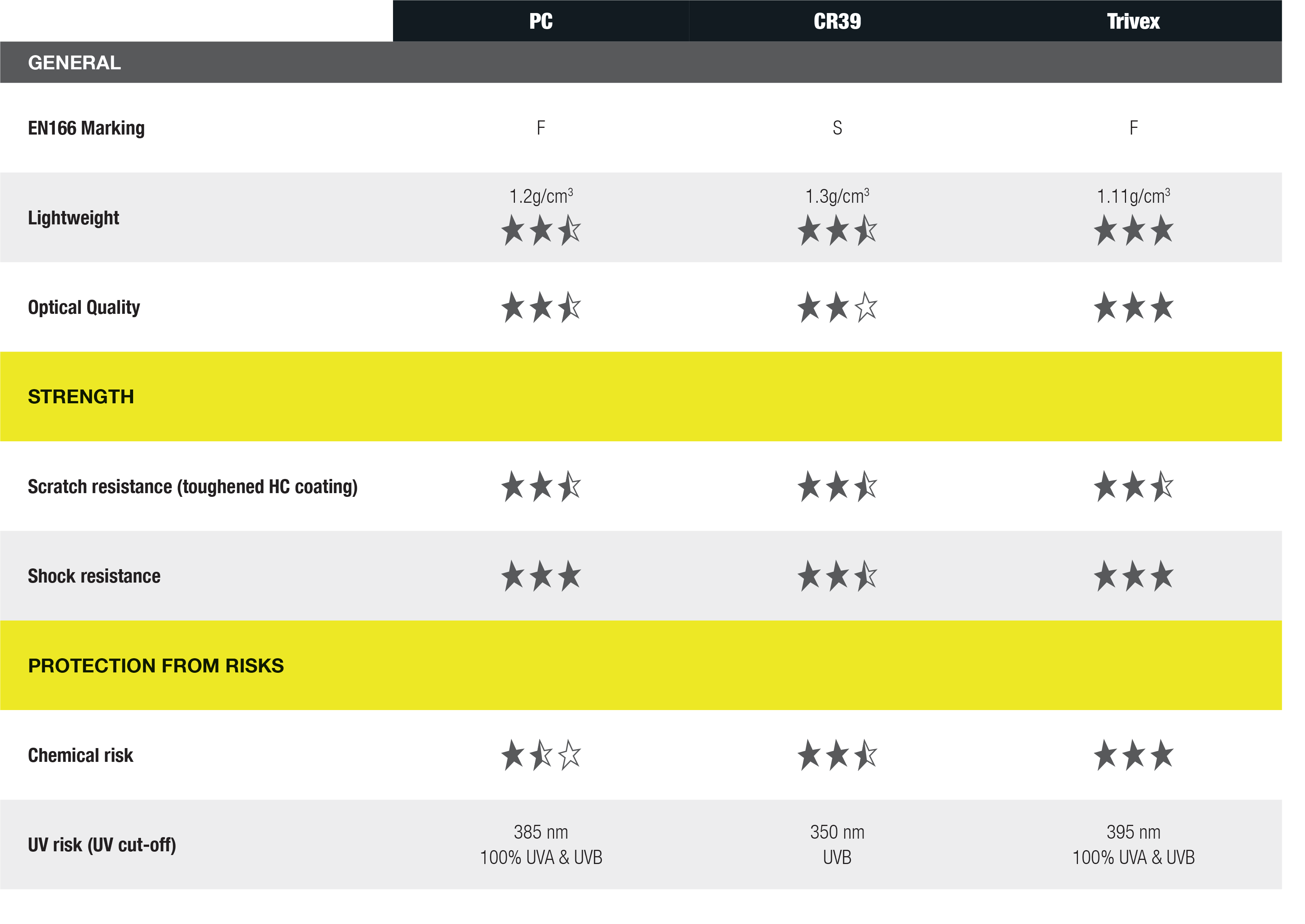

POLYCARBONATE

The main feature of polycarbonate is its resistance to impact. This material is by far the most resistant of all. Polycarbonate is 10% thinner than glass and 15% thinner than CR39. But it is a soft plastic and is therefore easily scratched.

An anti-scratch coating is applied as standard to remedy this issue. This material is particularly recommended for protection in the workplace.

Polycarbonate has the added advantage of absorbing all ultraviolet rays from 280 nm up to 380 nm (99.99%).

Lens markings = 1FCE

European standards EN166 - EN170 - EN172

Rating: 1.59

CR39

This is an organic resin lens, which is stronger than glass lens and 50% lighter and which absorbs part of ultra-violet rays.

On the other hand, they scratch more easily. To remedy this, a hard coating is applied to the lens. At equal power, they are thicker than glass or polycarbonate lenses.

Lens markings = 1SCE

European standards EN166 - EN170 - EN172

Rating: 1.50

TRIVEX

Trivex® offers the strength of polycarbonate and the optical quality of CR39. More durable than CR39 and highly resistant to chemicals, it is also one of the lightest materials (1.11g/cm³) and blocks 100% of UVA/UVB rays. However, it is more expensive and has a narrower correction range than CR39 or polycarbonate.

Lens markings =

1FCE (Anti-reflects and B-ZEN)

1FKCE (Hard Coating)

1 F KN CE (PLATINUM)

European standards

EN166 - EN170 (clear lenses)

EN166 - EN172 (tinted and photochromic lenses)

Rating: 1.53